In 1994 the Problem Laboratory of Vibration Reliability and Tightness of the Centrifugal Machines was created.

In 1994 the Problem Laboratory of Vibration Reliability and Tightness of the Centrifugal Machines was created.

The Laboratory is equipped with

- unique experimental stand for studying the dynamics of rotors in slotted seals, determine the static and dynamic characteristics of the seals with automatic control of leakage of liquids and gases

- stand for aerodynamic research

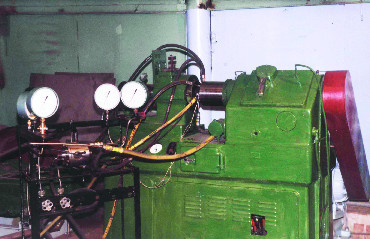

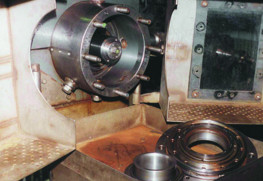

Stand for study of non-contact seals with high parameters (pressure is 5 MPa, shaft speed is 20,000 min-1). Stand for study of non-contact seals with high parameters (pressure is 5 MPa, shaft speed is 20,000 min-1). |

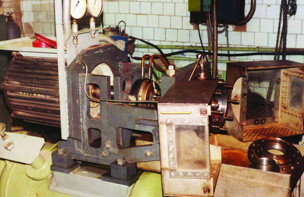

Stand for study of dynamic characteristics of gap seals. Stand for study of dynamic characteristics of gap seals. |

Aerodynamic stand. Aerodynamic stand. |

Installation for investigation of friction and wear of the contact seal, created on the basis of the friction machine. Installation for investigation of friction and wear of the contact seal, created on the basis of the friction machine. |

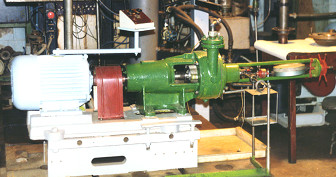

Stand for study of face gland seals. Stand for study of face gland seals. |

Stand for study of axial balancing devices of rotors of centrifugal machines. Stand for study of axial balancing devices of rotors of centrifugal machines. |

Stand for study of face hydrostatic seals created on basis of the console pump. Stand for study of face hydrostatic seals created on basis of the console pump. |

Laboratory hydraulic system. Laboratory hydraulic system. |

Installation for aerodynamic studies. Installation for aerodynamic studies. |

Installation for investigation of the radial gland seals. Installation for investigation of the radial gland seals. |

The device for determining the physical and mechanical properties of gland packings. The device for determining the physical and mechanical properties of gland packings. |

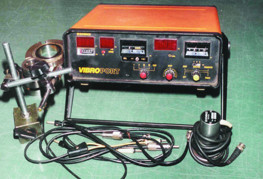

For research is used modern measuring equipment.

The presence of the laboratory can verify the theoretical results and bring them to practical use. Theoretical studies performed at a modern level using advanced computer technology, in particular, the software package ANSYS - recognized in the software world for the strength calculations and simulation of complex dynamic and hydrodynamic processes.

Research and Development:

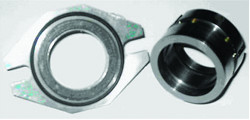

Impulse high-speed turbo pump mechanical seals. Impulse high-speed turbo pump mechanical seals. |

Contact rotary shaft seals. Contact rotary shaft seals. |

Impulse face seals of turbopump of liquid rocket engine. Impulse face seals of turbopump of liquid rocket engine. |

Mechanical gland seal. |

Locking impulse end seal. Locking impulse end seal. |

English

English  Українська

Українська